The classification survey can be divided into the following categories:

The classification survey can be divided into the following categories:

A. New ships surveyed during construction

B. Survey of existing ships

C. Extension of Classification special survey

A. New ships surveyed during construction

For newbuildings under construction, we will arrange for our qualified surveyors to be stationed at shipyards in order to conduct surveys in accordance with the Rules and the approved drawings.

B. Survey of existing ships

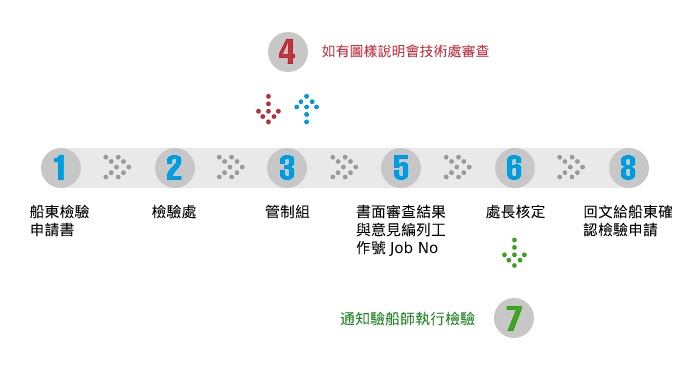

(a) Procedures for survey of existing ships

(The name of vessel , survey items, name and Tel Number of contact person, and time and place of survey shall be indicated on the survey application form)

(b) The scope of implementation regarding survey of existing ships is categorized based on CR Rules, and outlined as follows:

(1) Classification survey of existing ships

a. For ships which are classed with other classification societies, such as ABS, BV, LR, NK, DNV-GL and have been surveyed in accordance with the requirements of their rules, we accept the survey reports previously issued by other classification societies and maintain their survey status in principle. The survey items that are not yet due may be completed when they are due, whereas the surveys items already due shall be completed first. In general, a survey to the extent of an intermediate survey as specified in CR Rules is to be conducted, and the outstanding items from previous classification societies shall be dealt with.

b. For classification of an existing ship, the owner shall submit an application form (Application for New Ship / Existing Ship Entry Survey Form No. XM9), and copies of the certificates /reports issued by the previous classification society (please refer to the Abstract of Procedures for Application for Classification of Existing Ships and Issuance of International Convention Certificates as Attachment 2) to this Society for approval.

c. For initial classification of an existing ship not classed with any other classification society, the owner shall submit copies of the survey records and supporting documents issued by the previous classification society. We will review and consider such records, documents, and ship age in order to decide on the scope of classification survey. All the survey items which are listed in the survey records and are almost due or overdue shall be completed.

(2) Periodical survey of existing ships

a. Class Special Survey of Hull (HRS)

b. Class Special Survey of Machinery (MRS)

c. Class Special Survey of Ref. Machinery (RRS)

d. Class Special Survey of Auto. & Rem. System (AUR)

e. Special Survey of Inert Gas System (IGR)

f. Propeller Shaft Condition Monitoring Special Survey (PCMS)

g. COW System Special Survey (OWS)

h. Dynamic Positioning System Special Survey (DPS)

i. Class Annual Survey of Hull (HAS)

j. Class Annual Survey of Machinery (MAS)

k. Class Annual Survey of Ref. Machinery (RAS)

l. Class Annual Survey of Auto. & Rem. System (AUA)

m. Annual Survey of Inert Gas System (IGA)

n. Propeller Shaft Condition Monitoring Annual Survey (PCMA)

o. COW System Intermediate Survey (OWI)

p. Dynamic Positioning System Annual Survey (DPA)

q. Class Intermediate Survey (CIS)

r. Bottom Survey (BTS)

s. Propeller Shaft Survey (TSS)

t. Auxiliary Boiler Survey (ABS)

u. Auxiliary Boiler Annual Survey (ABA)

v. Planned Maintenance Scheme Annual Audit (PMSA)

w. Thermal Oil Heater Survey (THS)

x. Thermal Oil Heater Annual Survey (THA)

(3) Hull/Machinery Continuous Survey (HCS/MCS)

(4) Conversion Survey

(5) Occasional Survey

(c) Approval of extension survey of existing ships:

The owner shall submit documents stating the type of extension survey, the reason forsuch survey, and the extension period to this society for application.

a. Extensions of Bottom Survey

(i). There is to be a minimum of 2 examinations of the outside of the ship's bottom and related items during each 5-year Special Survey period. One such examination is to be carried out in conjunction with the Special Survey. In all cases the interval between any 2 such examinations is not to exceed 36 months.

(ii). An extension of examination of the ship's bottom up to 3 months beyond the due date may be granted in exceptional circumstances provided an occasional survey has been carried out satisfactorily with the following survey items required by the Society.

- Extensions up to 1 month

General examination afloat to determine the ship's fitness for continued service during the extension period is to include:- Examination and testing of the steering machinery as considered necessary

- Review of on board records to confirm satisfactory operation of the propulsion machinery

- Confirmation that no damages and/or grounding have occurred since the last attendance by the Surveyor.

- External examination of the saltwater systems with particular attention to nonmetallic expansion pieces (if fitted), sea valves and their attachments to the sea chests/side shell

- Re-examination of any condition of class with a view to confirm condition satisfactory for service through the subject extension period

- All class surveys are current

- In addition, when the requested extension date exceeds 36 months from the previous drydocking survey, an examination of the underwater body by an In-Water Survey company approved by the Society is required (with the underwater body sufficiently clean and water clear enough for a meaningful examination) including rudder, propeller, visible parts of the stern bearing assembly and sea chests.

- Extensions up to 3 month

General examination afloat to determine the ship's fitness for continued service during the extension period is to include:- Examination and testing of the steering machinery as considered necessary

- Review of on board records to confirm satisfactory operation of the propulsion machinery

- Confirmation that no damages and/or grounding have occurred since the last attendance by the Surveyor.

- External examination of the saltwater systems with particular attention to nonmetallic expansion pieces (if fitted), sea valves and their attachments to the sea chests/side shell

- Re-examination of any condition of class to confirm condition satisfactory for service through the subject extension period

- All class Surveys are current.

- In addition, when the requested extension date exceeds 36 months from the previous drydocking survey, the following examinations are required:

An examination of the underwater body by an In-Water Survey company approved by the Society, (with the underwater body sufficiently clean and water clear enough for a meaningful examination), including rudder, propeller, visible parts of the stern bearing assembly and sea chests. Strut/stern bearing and rudder clearances to be determined as possible and confirmed satisfactory for continued service during subject deferral period. Where not practical, rudder pintle clearances may be dispensed with if the attending Surveyor is satisfied with the physical and securing arrangements of the pintle. Oil-lubricated stern bearings to be visually checked for oil leaks

b. Extensions of propeller shafts and tube shafts

(i). Propeller shaft survey shall be carried out at intervals of 3 years to 5 years (depending on the types, bearings and survey methods)

(ii). An extension with specified period may be granted by the Society, when requested by the Owner, provided the extension survey is carried out to the satisfaction of the Surveyor with the following survey items required by the Society. Pre-requisites to satisfactorily verify should be carried out before extension survey.

- Oil lubricated shafts or closed loop system fresh water lubricated shafts (closed system)

- Extension up to 2.5 years. The survey is to consist of:

- Checking and recording the bearing wear down measurements, as far as practicable.

- Visual Inspection of all accessible parts of the shafting system.

- Verification that the propeller is free of damages which may cause the propeller to be out of balance.

- Verification of the effectiveness of the inboard seal and outboard seals

- Extension up to 1 year. The survey is to consist of:

- Visual Inspection of all accessible parts of the shafting system.

- Verification that the propeller is free of damages which may cause the propeller to be out of balance.

- Verification of the effectiveness of the inboard seal and outboard seals

- Extension up to 3 months. The survey is to consist of:

- Visual Inspection of all accessible parts of the shafting system.

- Verification of the effectiveness of the inboard seal

- For all types of propeller connections, the interval between two consecutive surveys may be extended after the execution of extension survey as follows:

- Extension up to a maximum of 2.5 years: no more than one extension can be granted. No further extension, of other type, can be granted.

- Extension up to a maximum of 1 year: no more than two consecutive "one year extensions" can be granted. In the event an additional extension is requested the requirements of the "2.5 year extension" are to be carried out and the shaft survey due date, prior to the previous extension(s), is extended for a maximum of 2.5 years.

- Extension up to a maximum of 3 months: no more than one "3 months extension" can be granted. In the event an additional extension is requested the requirements of the "one year extension" or "2.5 years extension" are to be carried out and the shaft survey due date, prior to the previous extension, is extended for a maximum of 1 year or 2.5 years.

- Extension up to 2.5 years. The survey is to consist of:

- Water Lubricated shafts (open systems)

- Extension up to 1 year. The survey is to consist of:

- Visual Inspection of all accessible parts of the shafting system.

- Verification that the propeller is free of damages which may cause the propeller to be out of balance.

- Checking and recording the clearances of bearing.

- Verification of the effectiveness of the inboard seal

- Extension up to 3 months. The survey is to consist of:

- Visual Inspection of all accessible parts of the shafting system.

- Verification that the propeller is free of damages which may cause the propeller to be out of balance.

- Verification of the effectiveness of the inboard seal

- For all types of propeller connections, the interval between 2 consecutive surveys may be extended after the execution of extension survey as follows:

- Extension up to a maximum of 1 year: no more than 1 extension can be granted. No further extension, of other type, can be granted.

- Extension up to a maximum of 3 months: no more than 1 "3 months extension" can be granted. In the event an additional extension is requested the requirements of the "1 year extension" are to be carried out and the shaft survey due date prior to the previous extension is extended for a maximum of 1 year.

- Extension up to 1 year. The survey is to consist of:

c. Boiler Surveys

(i). a minimum of 2 surveys is to be carried out during each 5-year Special Survey period. One such survey is to be carried out in conjunction with the Special Survey. In all cases, the interval between any 2 such surveys is not to exceed 36 months. Annual Examinations are to be carried out in every year.

(ii). An extension of the survey up to 3 months may be granted by the Surveyor in exceptional circumstances, provided a survey is carried out in accordance with the following survey items.

- External examination of the boiler

- Boiler safety valve relieving gear (easing gear) is to be examined and operationally tested

- Boiler protective devices (alarms and shutdowns) operationally tested

- Review of the following records since the last Boiler Survey : Operation record, maintenance record, repair history record, and feedwater chemistry record.

d. Extension of Special Surveys

- The Special Survey is to be subjected to surveys at the fixed intervals not exceeding 5 years

- If a ship at the time when the Special Survey is due but not in a port in which it is to be surveyed, the Society may upon the Owner's written request in advance in each case extend a period not exceeding 3 months. Such extension is, however, only to be granted for allowing the ship to complete its voyage to the port in which it is to be surveyed, and only in cases where it is considered proper and reasonable to do so. A maximum 3 months extension of Special Survey beyond the due date may be granted provided an occasional survey has been carried out satisfactorily based on a scope of Annual Survey and the additional items considered by the Society.

Certification of Material, Machinery or Equipment

a. Criterions for certification of material, machinery or equipment are different in the purpose,For marine use product : CR Rule set(s) and/or International Convention(s) issued by International Maritime Organization. Specific standards may be complied in case of such standards were indicated in the documentation, calculation or drawing of design;For non-marine use product : Designated standard(s) addressed by applicant of certification may be complied.

b. Survey of material, machinery or equipment can only be carried out after Working Approval / Product Type Approval if deemed necessary by this Society. Otherwise, survey requirements detailed as applicable CR Rule set(s) shall be complied.